|

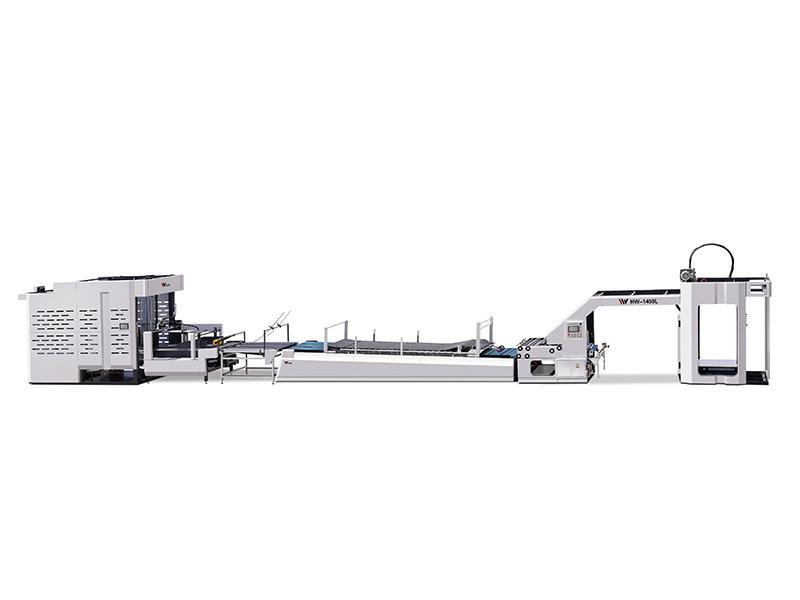

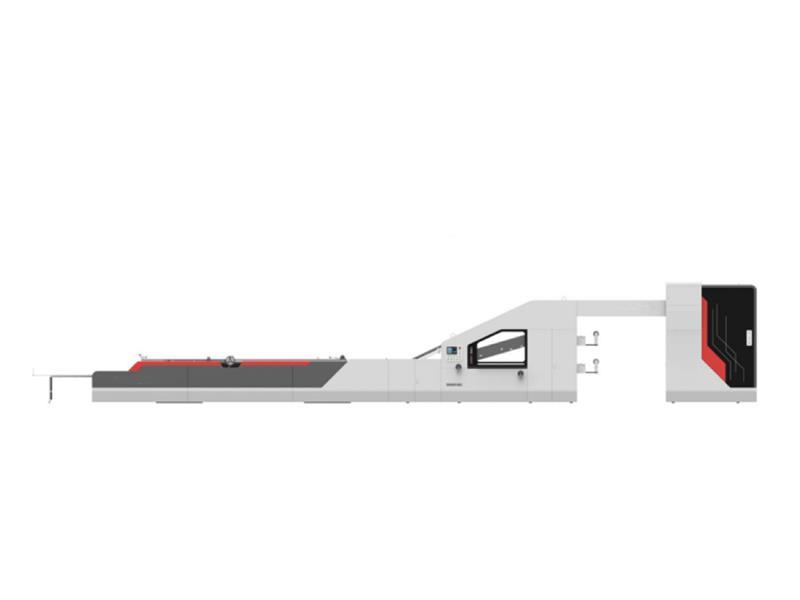

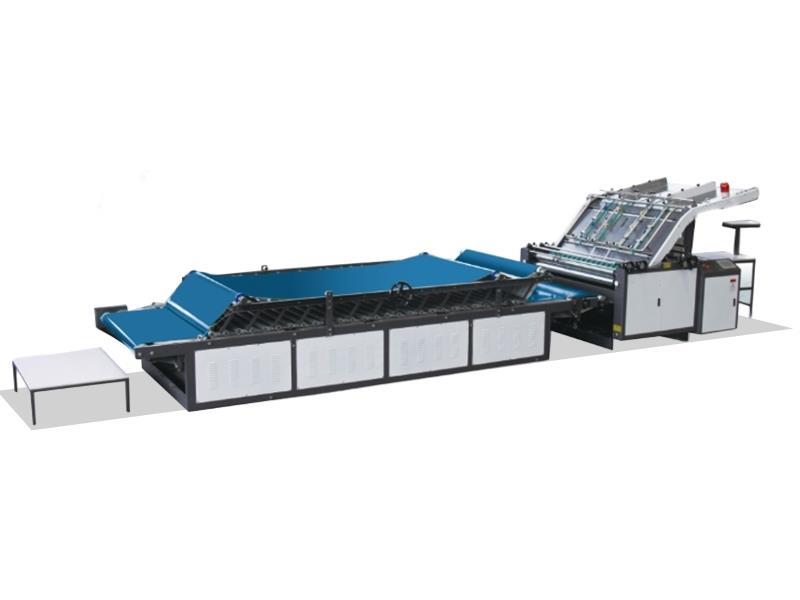

Model |

HW-1200 |

|

|

Max. Sheet Size (W*L) |

1200*1200mm |

|

|

Min. Sheet Size (W*L) |

390*360mm |

|

|

Thickness |

Top sheet |

120~600g/m² |

|

Bottom sheet |

0.5-10mm(B,A,AB,E flute, etc.) |

|

|

Laminating Accuracy |

±1mm |

|

|

Max. Speed |

12000p/h 150m/min |

|

|

Power |

22KW |

|

|

Dimension L*W*H |

12.5m*2m*2.7m |

|

|

Height of Bottom Paper |

400mm |

|

|

Height of Top Paper |

1800mm |

|

|

Weight |

5.5T |

|

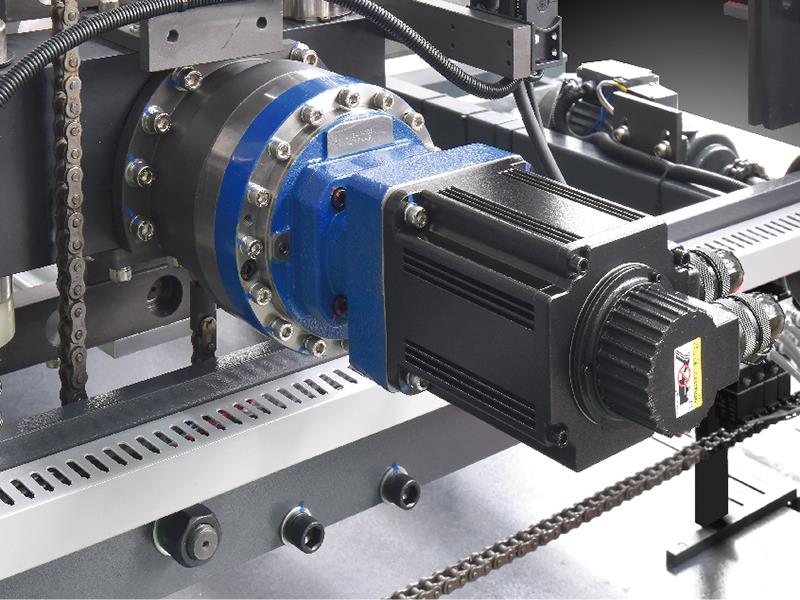

Bottom Paper System

The imported servo motor is used to drive the bottom paper conveying structure of the suction belt, which is matched with Japan Nida suction belt and SMC high-frequency valve, so that the conveying distance of the bottom paper (corrugated and paperboard) is accurate and smooth.

When the pit paper is warped, the pneumatic layering can press the front end of the pit paper to ensure smooth paper production.

Up Paper Feeder Section

Adopt four - suction and four - feeding structure, conjugate CAM structure, stable and reliable paper feeding.

The spool is easy to disassemble and clean.

When the pit paper is warped, the pneumatic layering can press the front end of the pit paper to ensure smooth paper production.

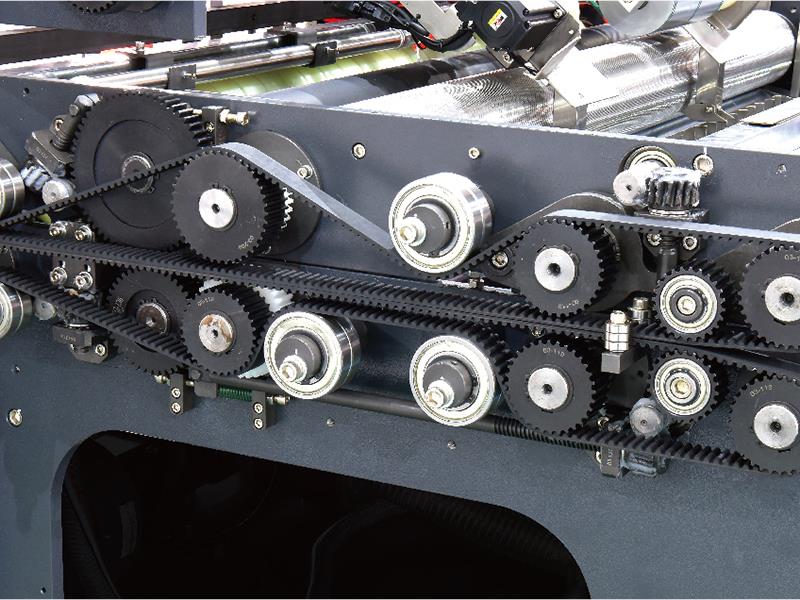

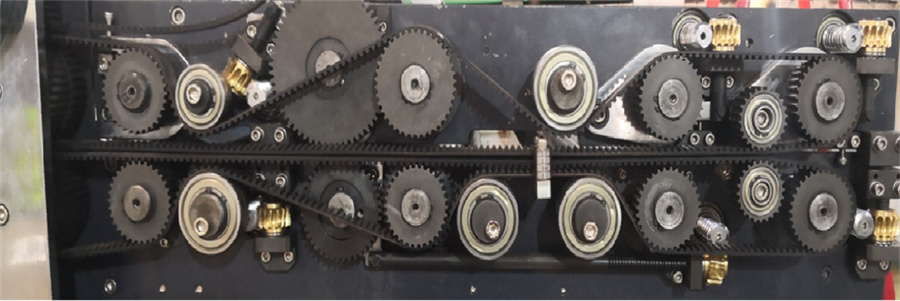

Convey System

Power transmission evenly distributed, the whole machine adopts imported double-sided tooth synchronous belt transmission, free maintenance. Bottom noise. High efficiency.

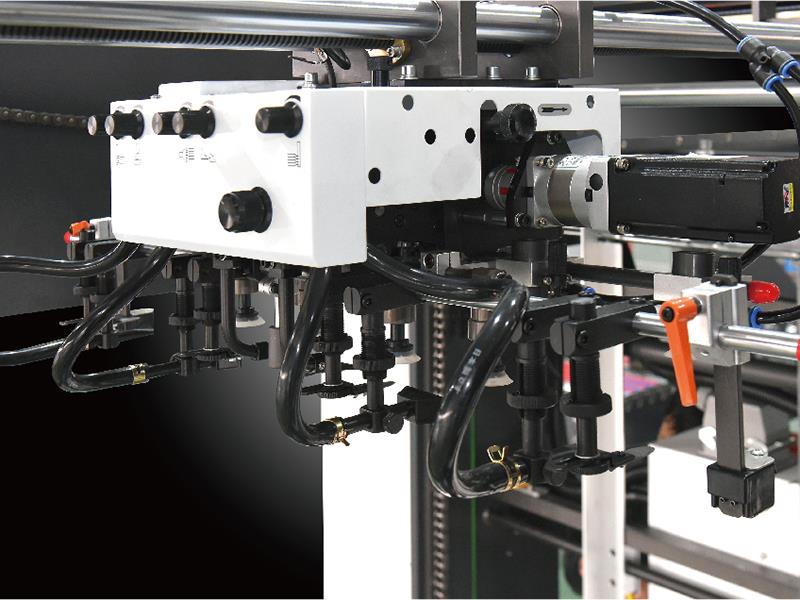

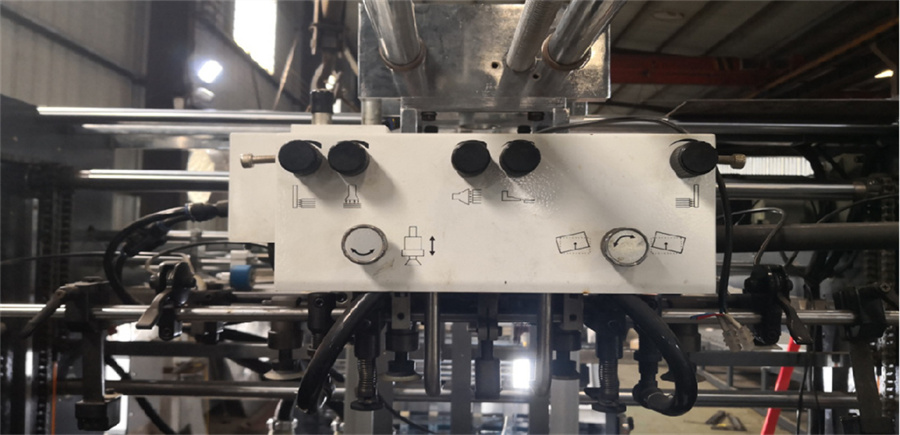

Positioning And Gluing System

High precision stainless steel knurled rubber roller, never rust, after fine grinding to ensure uniform gluing

The specially processed copper block ensures that the rubber roller running at high speed will not throw glue and overflow glue It can adjust the backflow of glue to ensure the cleanliness of equipment and the service life of bearings.

The error value between front paper and base paper is controlled by multiple groups of photoelectric detection and calculation The side servo motor compensates the surface paper to a predetermined position for precise alignment

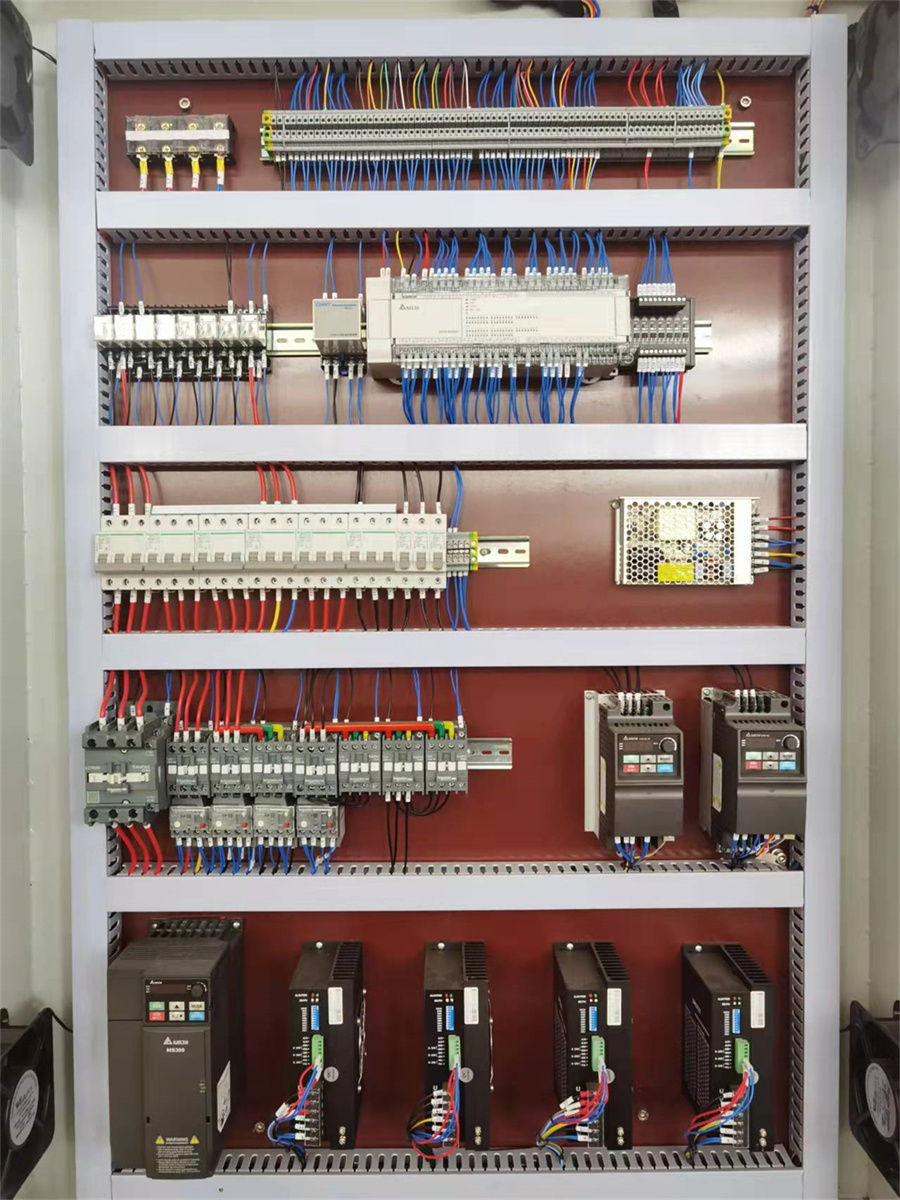

Electrical Control System